|

Applications Summary

Compliance Monitoring

Use the 7600 ION to summarize power quality

measurements into simple pass/fail indicators. Monitor compliance with

international standards such as EN50160, IEC 61000-4-7 (harmonics), and

IEC 61000-4-15 (flicker). Or configure the unit for IEEE 519-1992, IEEE

1159 and SEMI F47.

Disturbance Analysis

Unique dynamic-ranging inputs maintain revenue

accuracy at the regular measurement range while simultaneously capturing

large-scale disturbances other meters can miss. Discover the sources of

power quality events, harmonics, and voltage sags/swells. Analyze problems

and avoid repeat interruptions.

Cost Allocation & Billing

Determine cost centers, identify demand control

opportunities and check energy consumption patterns.

Demand & Power Factor Control

Avoid penalties with automated load shedding,

scheduling, peak shaving or capacitor bank control.

Load Studies & Circuit Optimization

Determine the capacity of your electric network

and run at peak efficiency. Perform load trending.

Equipment Monitoring & Control

Improve process yields and extend equipment

life. Meter utilities including gas, steam and water.

Preventative Maintenance

Set up alarms to warn of pending problems.

Log events and alarms for all critical conditions.

|

Features Summary

Measurements

- Exceeds Class 0.2 revenue accuracy

- Instantaneous 3-phase voltage, current, frequency,

power factor

- Energy: bi-directional, absolute, net, time-of-use,

loss compensation

- Demand: sliding window, predicted, thermal

- Harmonics: individual & total harmonic distortion

up to the 63rd (127th with Pegasys Software)

- Transient detection, 65 microseconds @ 60 Hz, (78

microseconds @ 50 Hz) & sag/swell recording

- Waveform recording at 256 samples per cycle

- Clamp-on CT option

Communications

- Web server, Meter M@il®

allow distribution of metered data and alarms over the Internet

- Optional built-in modem with ModemGate™ to allow

modem access for 31 other devices

- 10Base-T or 10Base-FL Ethernet port option with EtherGate™

for direct data transfer from Ethernet to as many as 31 RS-485 devices

- Two RS-485 ports, one switchable to RS-232

- One front panel optical port

- Modbus™ RTU and DNP 3.0 protocol support

On-Board Data Logging

- Scheduled or event-driven logging for hundreds of

parameters

- Sequence-of-events & min/max logging

Setpoints for Control and Alarms

- Setpoint on any parameter or condition

- 1 second or ½ cycle operation

Inputs and Outputs

- 8 digital inputs for status/counter functions

- 7 relay outputs for control/pulse functions

- Optional analog inputs and outputs

|

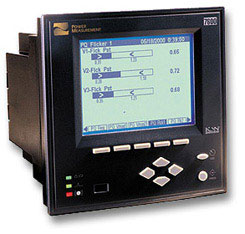

High

Visibility Energy and Power Quality Compliance Meter

High

Visibility Energy and Power Quality Compliance Meter